Like so many nice concepts, the BOA Match System began off as a manner for Gary Hammerslag to enhance his passion. Previous to transferring to Steamboat Springs, CO within the mid-90s, Gary labored within the medical trade and revolutionized the angioplasty course of together with his patented units that relied on skinny metallic wires. After promoting his firm, his new objective was to snowboard as a lot as attainable.

On the time, all snowboard boots relied on laces to tighten and Gary knew there needed to be a greater manner. Drawing on his expertise within the medical world, the primary BOA prototype was born – a real boat anchor. Phrases can’t put together you for the way heavy the primary prototype snowboard boot truly is. If you happen to go to BOA in Denver, you possibly can ask to really feel it for your self.

That first proof of idea shortly advanced right into a a lot lighter and easy-to-adjust system that was first launched in 2001 with BOA’s first two companions, K2 and Vans. After launching with snowboarding, BOA first moved into the world of biking after partnering with Specialised in 2005.

Model Companions and Classes

Quick ahead to the current, and BOA at present works with roughly 350 lively model companions (35-40 of these are biking manufacturers). And that’s with “turning down 99.9% of latest inquiries from potential prospects.” That reluctance to tackle new companions is because of BOA’s need to work instantly with the manufacturers to make the very best product attainable – not merely to only ship them BOA dials and laces off the shelf.

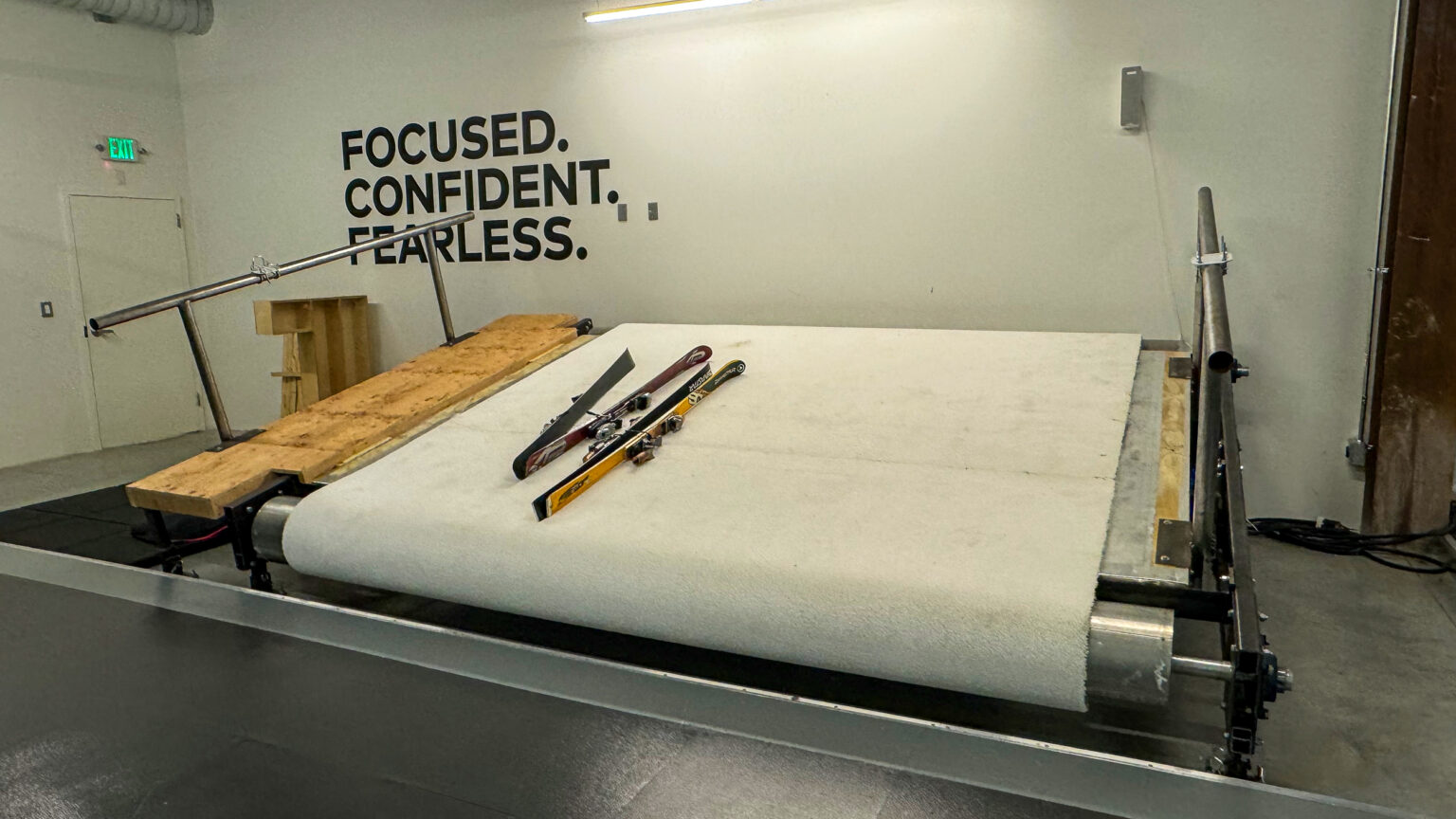

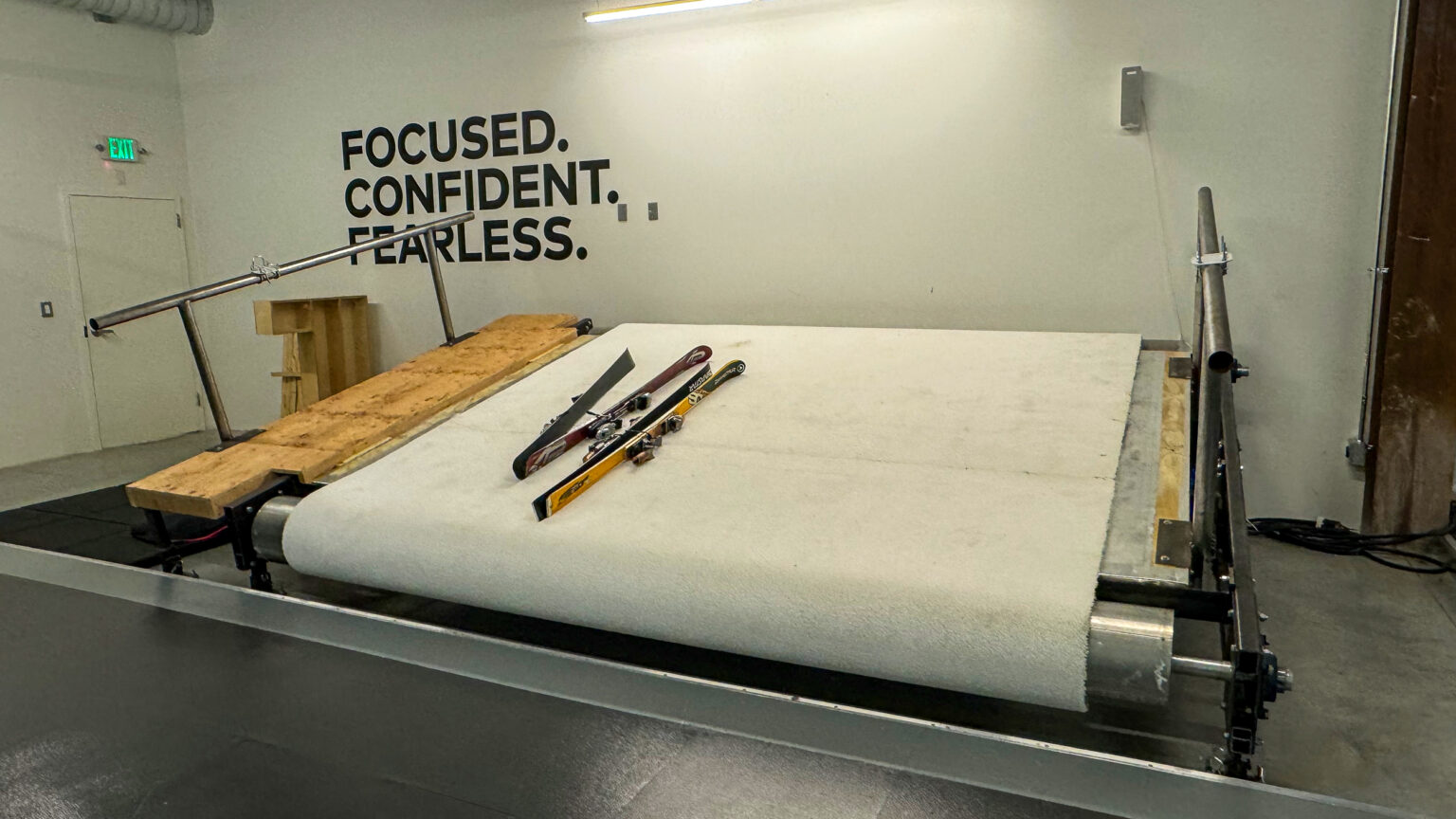

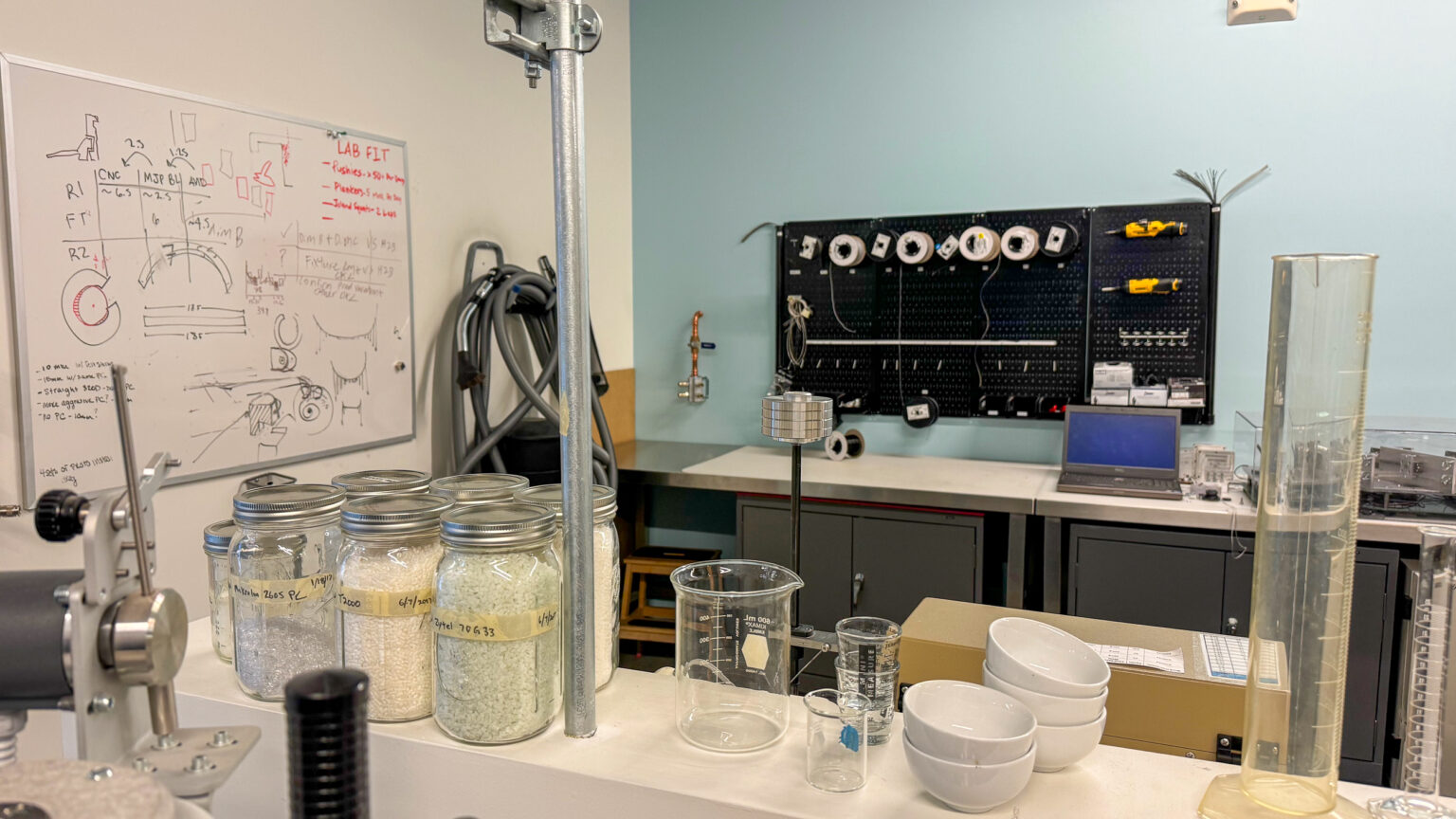

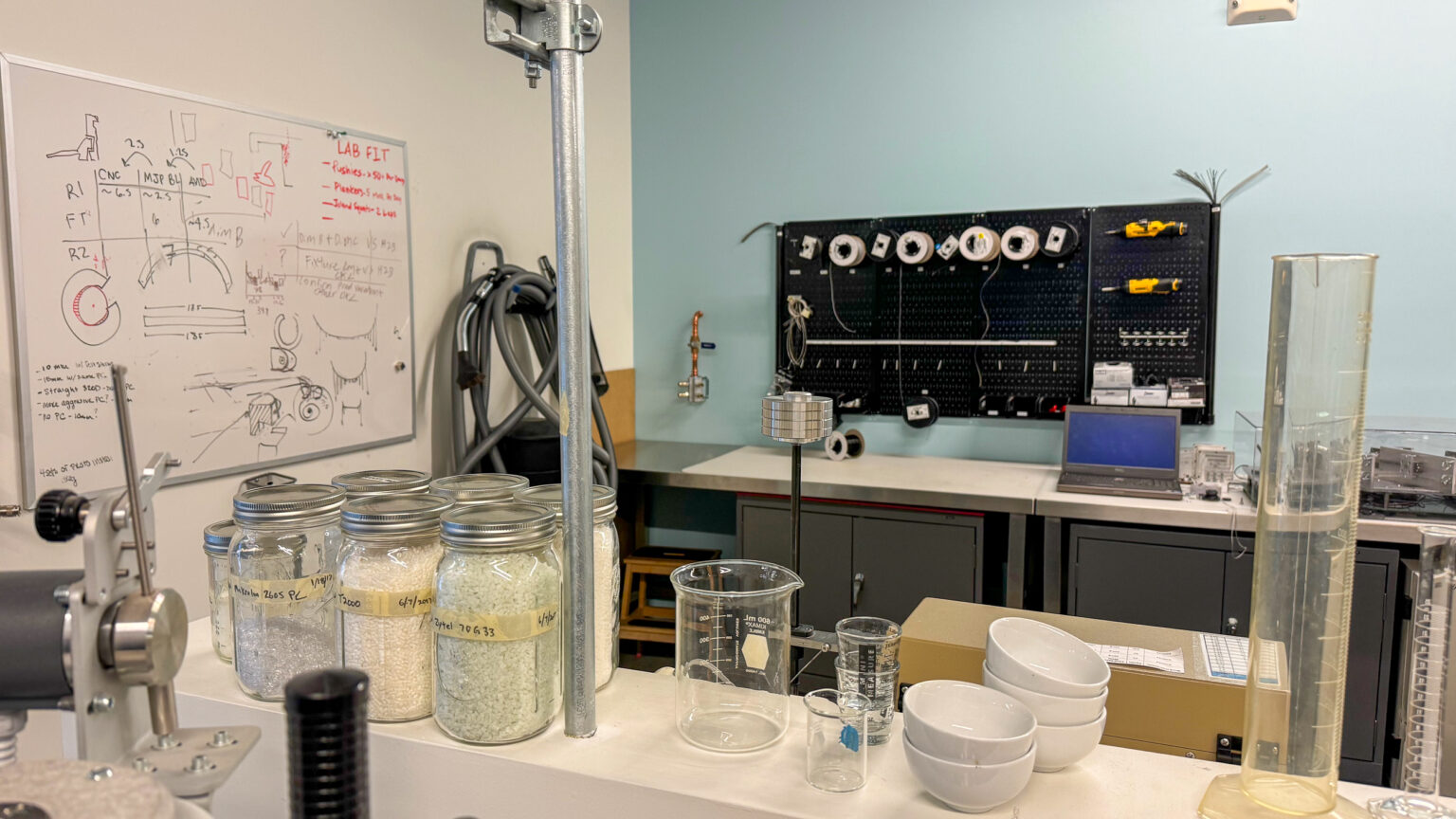

That need to create the very best product attainable is on full show at their latest headquarters within the RiNo space of Denver, CO. Whereas the brand new constructing is only a stone’s throw from the earlier one, its elevated dimension has allowed BOA to achieve the mandatory area to basically create a miniature shoe manufacturing facility and check facility.

Creating their very own prototype footwear

Whereas BOA doesn’t have the flexibility to create the lowers and outsoles of footwear on-site, they do possess all the things needed to construct a shoe higher on-site. That enables them to reverse engineer and rebuild current fashions within the quest to construct higher methods.

Throughout one of many shows, we had been proven footwear that might simply be mistaken as manufacturing fashions. Solely they had been one-off prototypes created by the BOA lab. Even with the flexibility to obviously create their very own footwear, BOA says it would most likely by no means occur – they don’t need to compete with their companions.

As a substitute, they need to see how the shoe seems, how it may be executed, and perhaps most necessary of all, the way it will have an effect on the biomechanics aspect. The hunt for a extra environment friendly match is a giant purpose we had been introduced out to BOA HQ because it coincided with the launch of two new footwear that includes their PerformFit Wrap idea.

BOA Efficiency Match Lab

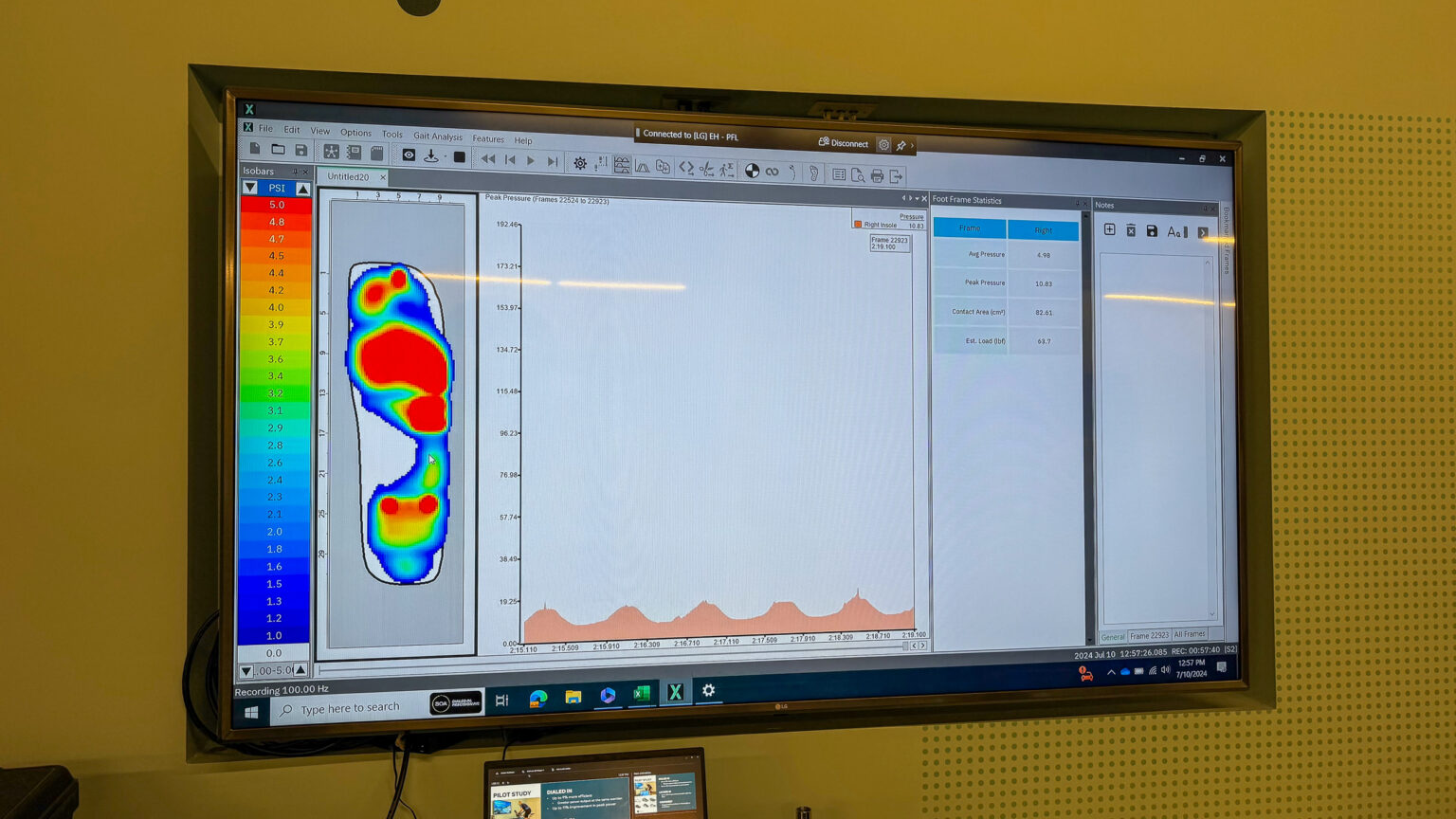

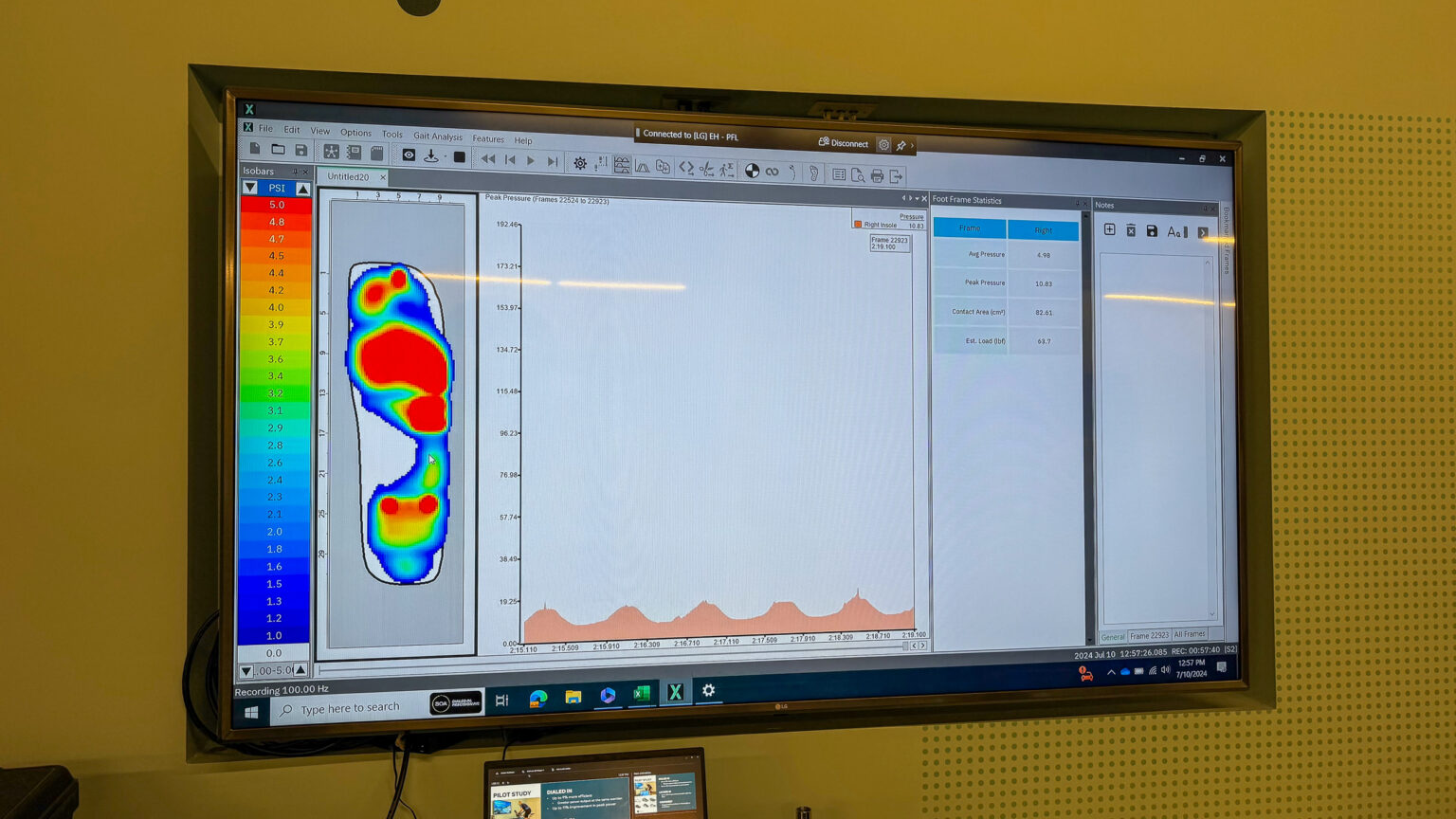

From the start BOA has been not nearly changing laces, however elevating the match. Analysis in their very own BOA Efficiency Match Lab has confirmed that a greater match will yield higher efficiency. By wrapping the midfoot and locking within the heel slightly than pinching down the middle of a ‘u-throat’ design, BOA has measured some spectacular positive aspects within the lab.

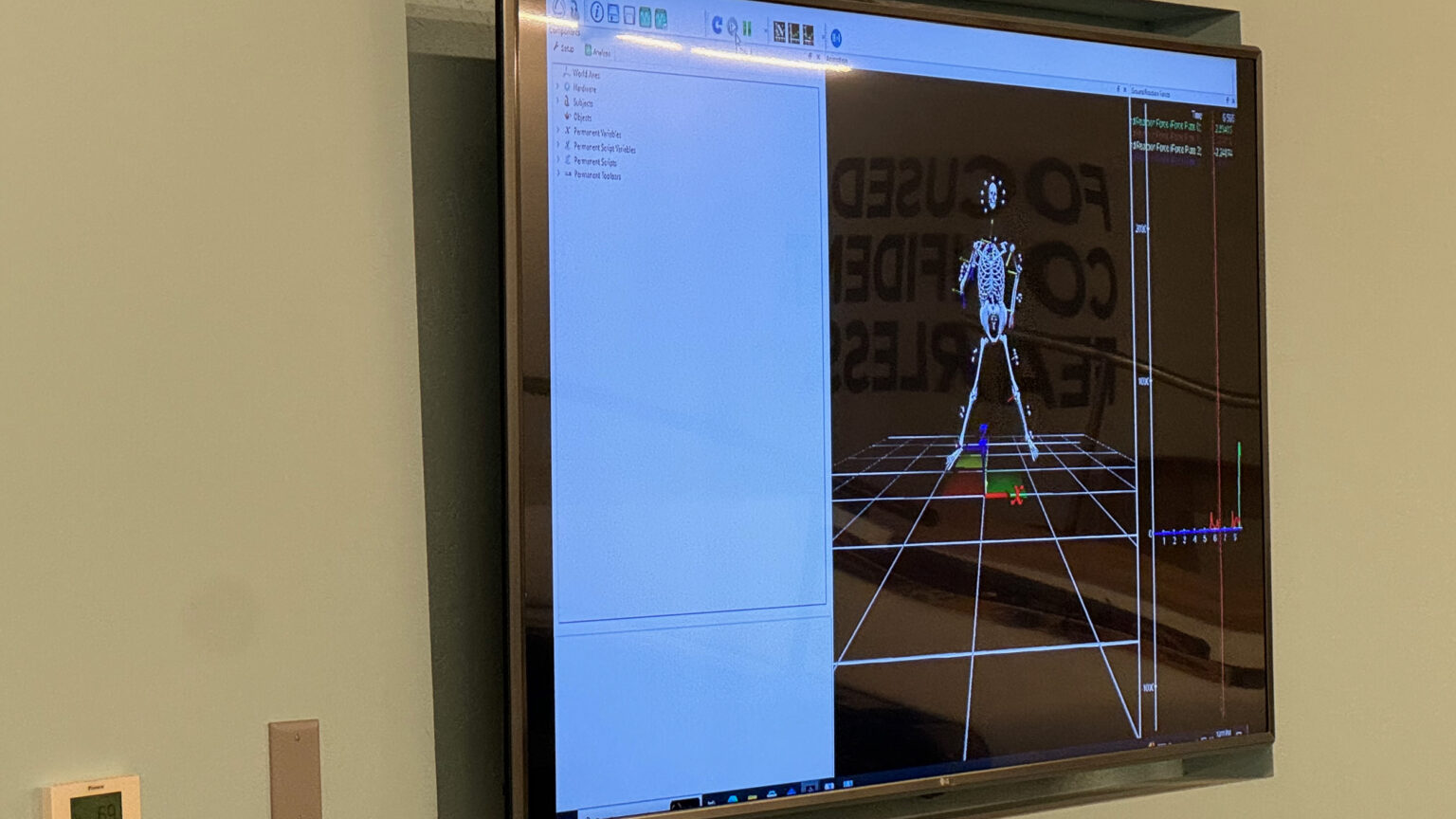

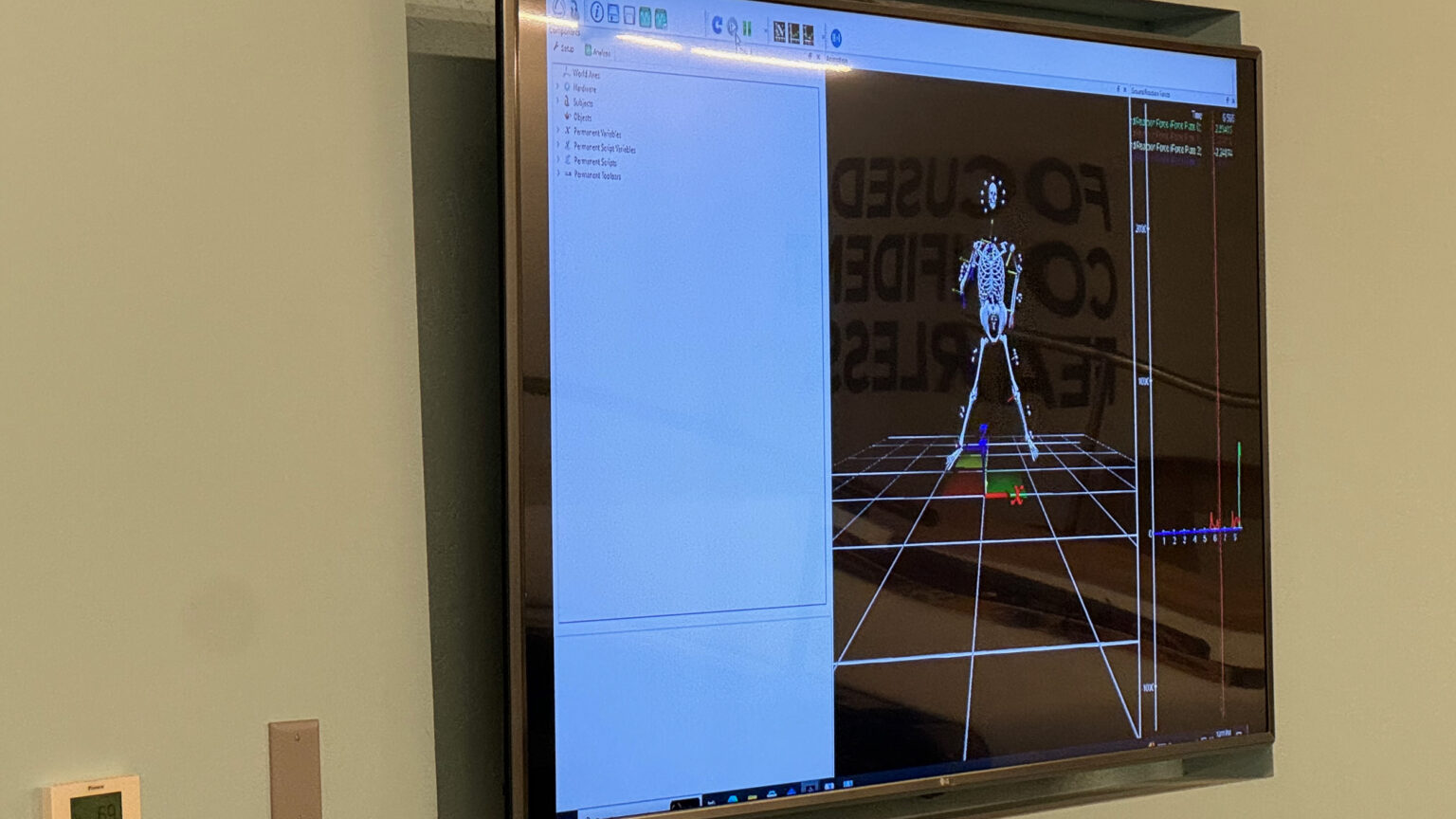

Damaged down into the Endurance & Well being, Agility & Pace, and Energy & Precision areas, the BOA Efficiency Match Lab has all the things from pressure plates that measure impacts as much as 1000x per second, to superior movement seize cameras, and a metabolic cart for a whole measurement of the athlete’s vitals.

In a pilot examine, BOA had 13 athletes check three totally different footwear – a Velcro strap mannequin, one with a single BOA dial in a traditional association, and one with their most superior PerformFit Wrap. Using strain mapping insoles, the metabolic cart, energy cranks, and movement seize, they’d every tester trip for five minutes steadily adopted by 2×15 second sprints. The outcomes confirmed as much as a “9% enhance in energy output whereas sustaining equal metabolic expenditure,” plus an “11% enhance in peak energy output throughout the sprints with the PerformFit Wrap shoe. Moreover, the shoe improved “strain distribution by as much as 10% for improved efficiency throughout each sprints and sustained using.”

“1000’s of hours of testing reveal that wrapping over the midfoot, locking the heel, and decreasing stress on the physique materially enhances match and efficiency. Our lab, along with our design groups, systematically evaluated easy methods to optimize PerformFit Wrap in biking by means of particular supplies and panel buildings that successfully conform to the foot, enabling extra environment friendly using and higher peak energy output throughout sprints.”

Dan Feeney, Ph.D., BOA Senior Director of Accomplice Product Innovation and Improvement.

After listening to the presentation on PerformFit Wrap and visiting the Efficiency Match Lab, one of many questions that got here to thoughts was how this idea compares to current shoe designs just like the Shimano XC903. In accordance with BOA, “whereas the Shimano XC903 (and different highway fashions hyperlink the Nimbl Final Glide, Trek RSL, and so forth.) leverage wrapping elements, the higher configuration Canyon Tempr CFR and Trip Ideas Tallac Mid BOA fashions make the most of unbiased panels activated by the micro-adjustable BOA Match System and wrapping from medial to lateral. Moreover, no less than two panels wrap over the dorsal ridge, which is a key element of our wrapping panels not seen with the different manufacturers.

It’s this particular configuration we’ve scientifically confirmed to safe the mid-foot and lock the heel again and down for the shared percentages round elevated peak energy and effectivity. PerformFit Wrap is the time period we use at BOA to indicate the sort of configuration scientifically validated to enhance efficiency.

BOA-powered fashions just like the Shimano RC and XC902, 903, in addition to just a few different choose fashions don’t instantly match the examined configuration, however supply some extent of wrap, and thus, probably supply some extent of comparable advantages.”

Improvement & Testing Lab

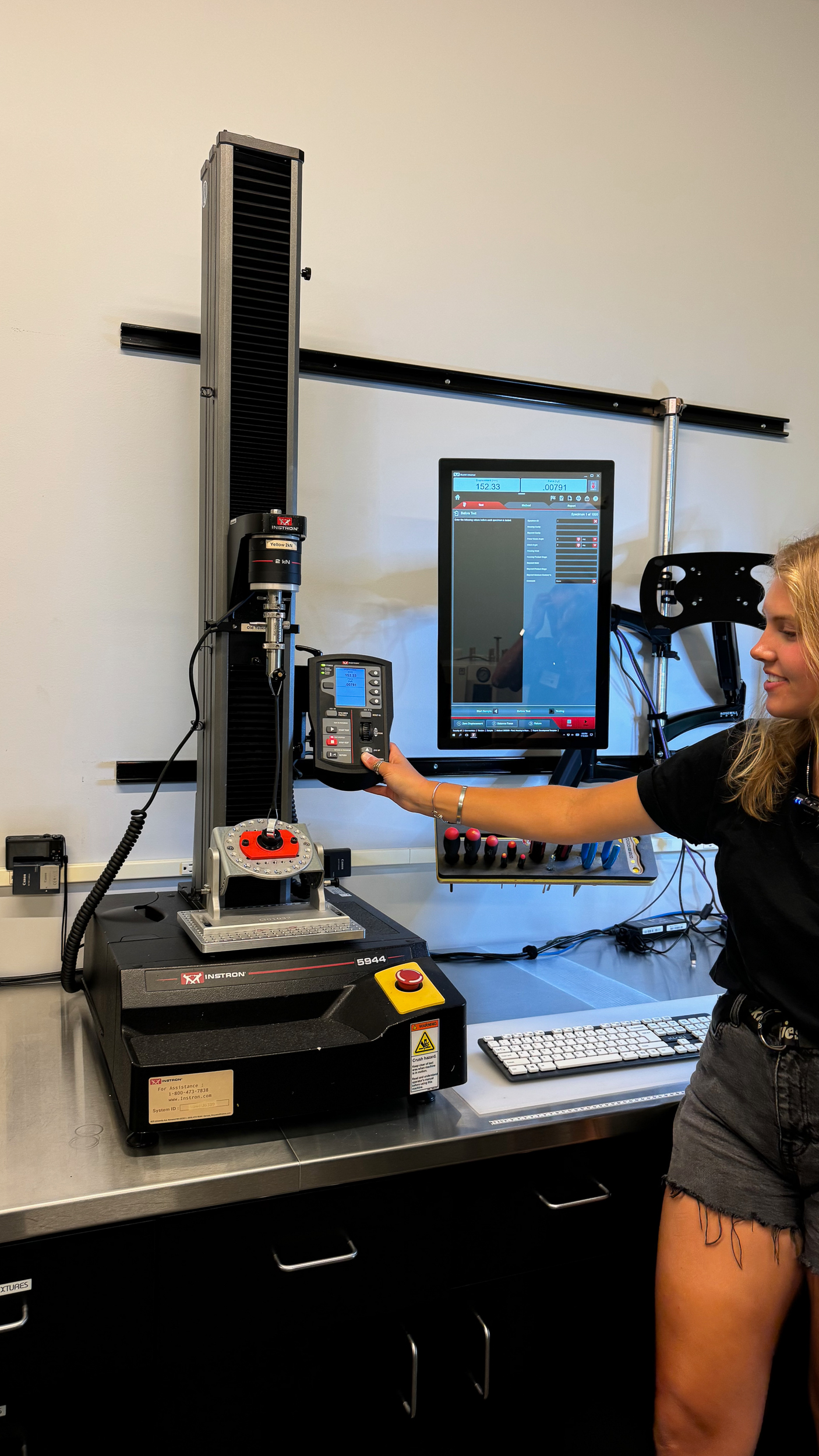

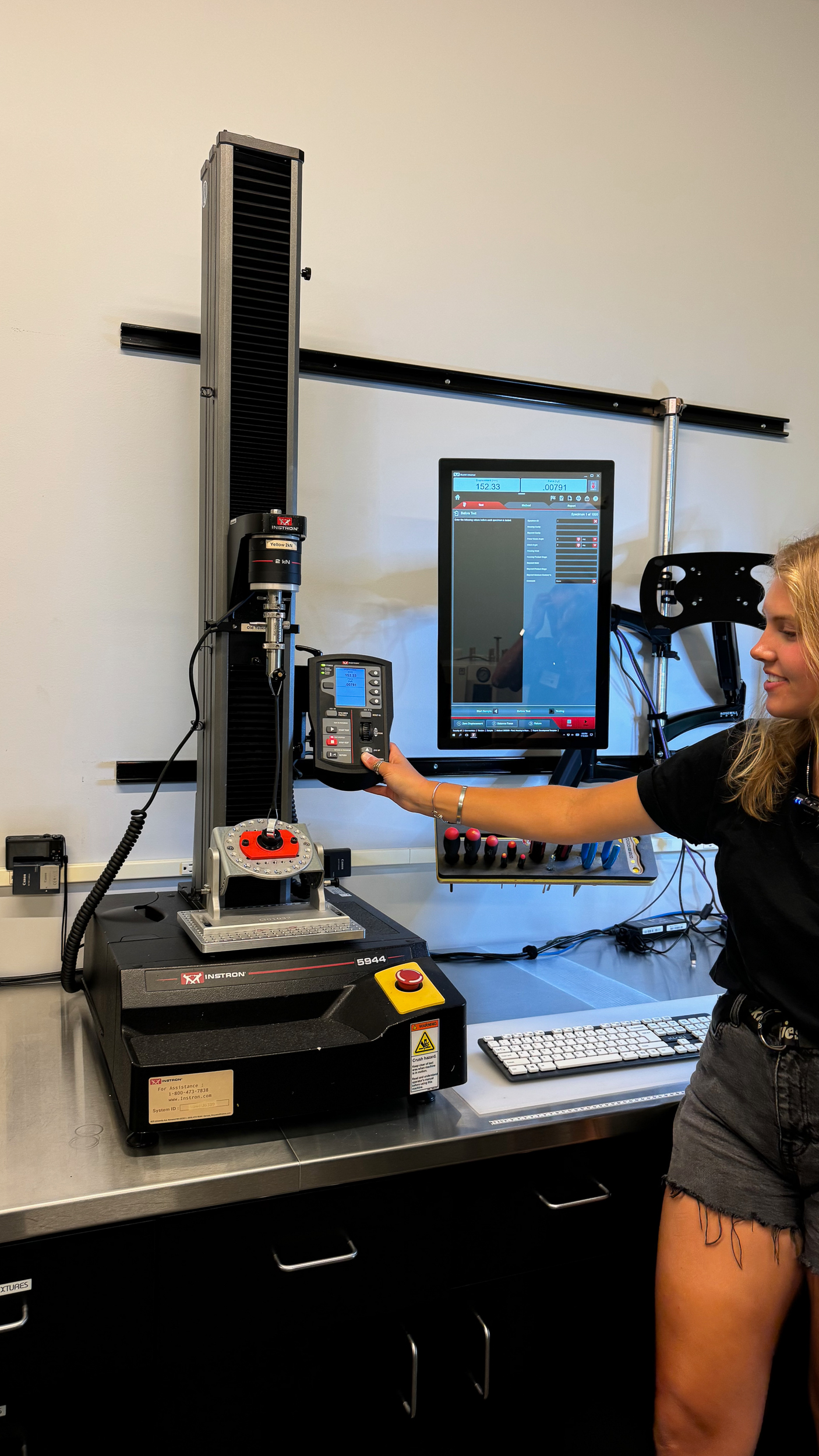

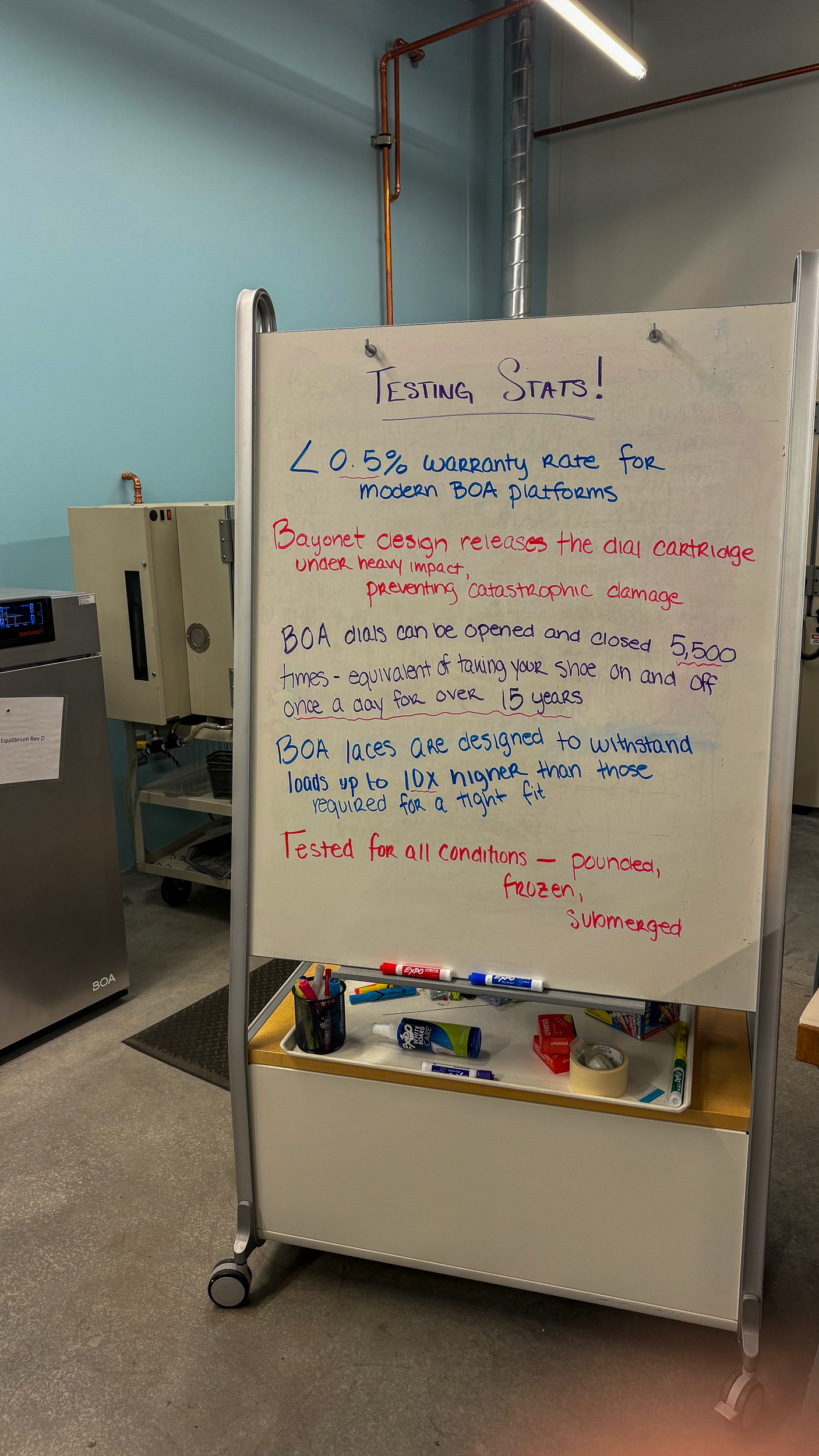

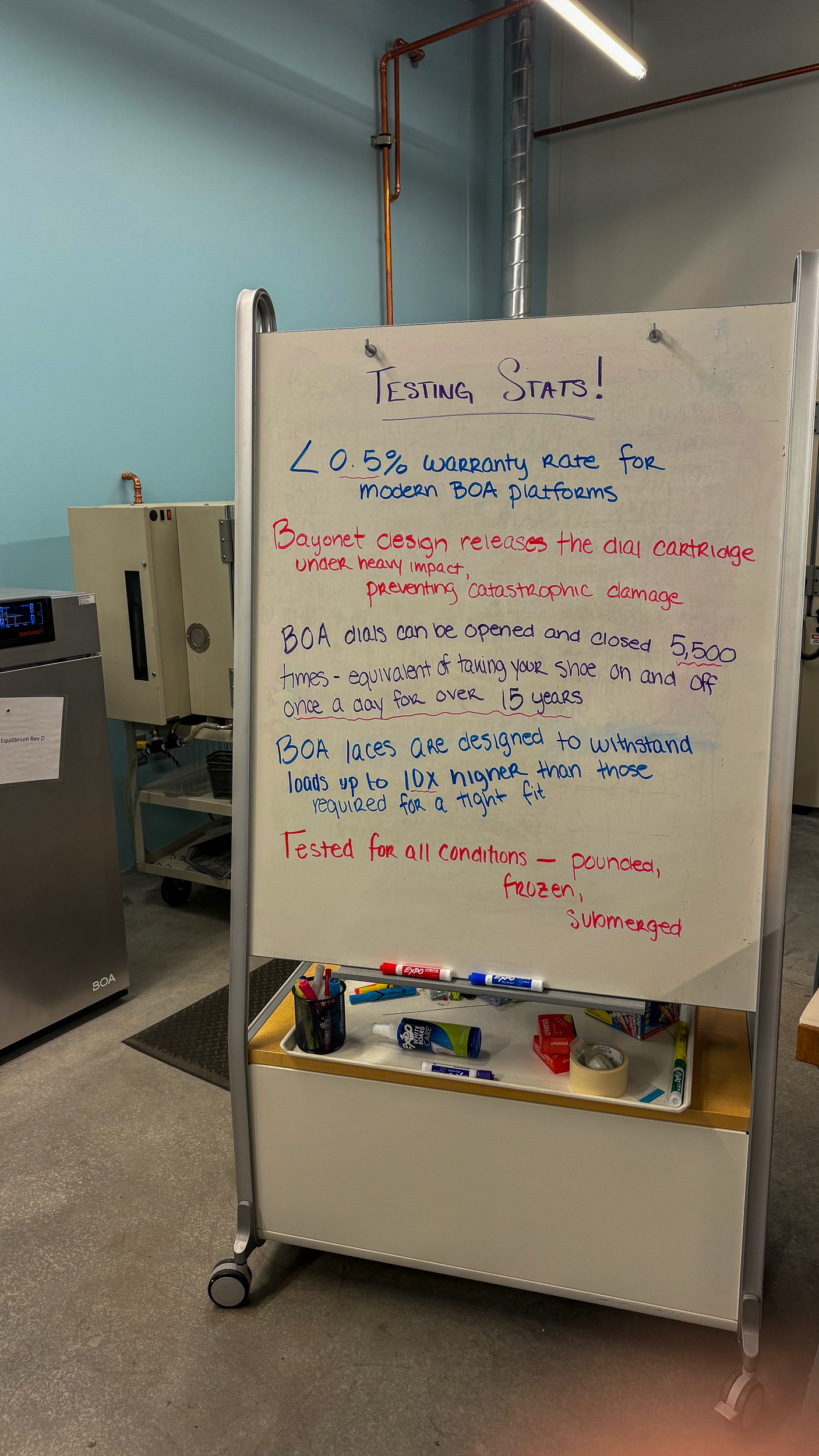

Along with the Efficiency Match Lab testing, BOA additionally has a full check lab on-site to make sure the dials are simply closed, opened, will final the lifetime of the product, and shouldn’t break simply. Their check facility contains torque gauges for optimum enter torques, the ‘Mr. Tornado’ to check dials to failure, a ‘cartridge to bayonet’ pulling check, environmental chambers with calibrated ISO sand, and lace information interplay checks which run till laces or guides fail.

To that impact, BOA claims to have a lower than 0.5% guarantee price (which they cowl with a lifetime assure). Their most typical supply of reducing warranties? That will be customers unintentionally reducing the cables when making an attempt to take away the tags on new footwear. Oops.

All that is to say that whereas it could look like your favourite shoe model could have simply slapped a BOA dial onto their newest higher, behind the scenes there’s a large quantity of testing and growth that has gone into that new shoe. Now, greater than ever, that testing is wanting into efficiency advantages and never simply enhancing the match.

And it usually begins proper right here, in Denver, Colorado.

BOAfit.com